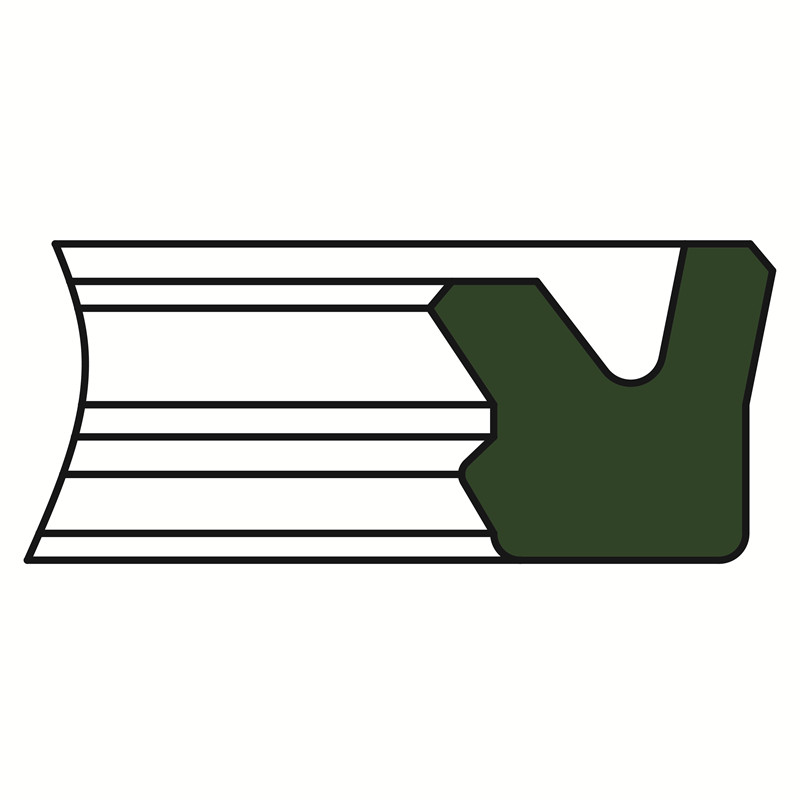

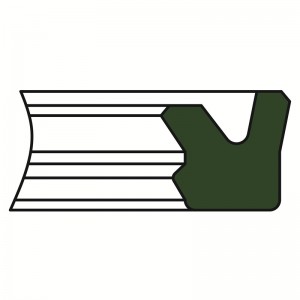

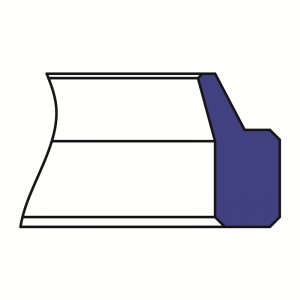

BS Hydraulic Seals – Rod seals

Description

BS is primarily designed to seal piston rods and plungers in heavy duty applications in mobile and stationary hydraulic systems.It is the most critical seal on any type of fluid power equipment preventing leakage of fluid from within the cylinder to the outside.

Material

Material:TPU

Hardness:92-95 Shore A

Color: Blue/Green

Technical Data

Operation conditions

Pressure:TPU: ≤31.5 Mpa

Speed:≤0.5m/s

Media:Hydraulic oils (mineral oil-based)

Temperature:-35~+110℃

Advantages

- Unusually high wear resistance.

- Insensibility against shock loads and pressure peaks.

- High resistance against e×trusion.

- Low compression set.

- Suitable for hardest working conditions.

- Sufficient lubrication due to pressure

medium between the sealing lips.

- lncreased sealing performance at zero pressure.

- Air penetration from outside is largely prevented.

- Easy installation.

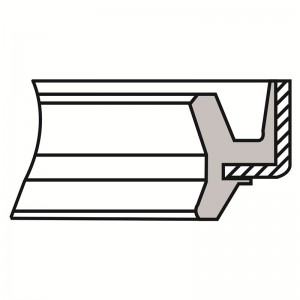

Direction for use

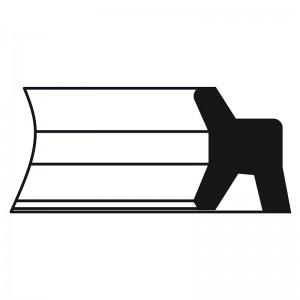

1. Clean the BS seal mating surfaces and shafts.

2. Ensure that the shaft is dry and free of grease or oil, especially in the absence of axial support.

3.Such a group of parts should have an axial gap. To avoid damage to the sealing lip, do not pull the seal on the sharp edge during installation..

4.These seals are typically incorporated into closed channels. Special installation tools are required where the entrance is restricted..

5. Verify whether the BS seal is evenly stretched around the shaft

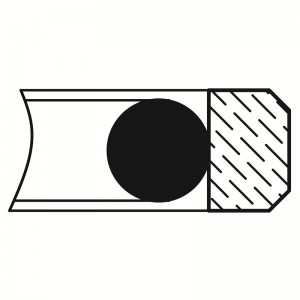

Installation

Such seals should have an axial gap. In order to avoid any damage to the lip, do not pull the seal on the sharp edge during installation. These seals can usually be fitted into closed grooves. Where access is restricted, special installation tools are required.